Magna-Track Connectors – How They Work / Features & Benefits

The Following Video demonstrates an unscripted / unrehearsed installation of a filter screen on a small refrigeration unit using the Magna-Track Magnetic Mounting Filters

Installation is completed in under 6 minutes – WOW!

No Drill / No Screws / No Problem!

The new Magna-Track™ magnetic air intake filters combine durable track connectors and high energy magnets to create a powerful magnetic mounting system that is ideal in applications where mounting screws are not desired. Use of the Magna-Track connectors with either the PVC or Anodized Aluminum Track magnetically suspends the track while retaining it flush to the face of the connection point ensuring that there are no perimeter gaps; Further, because all magnets are strongest when pulled perpendicular to the attachment surface and weakest when sliding parallel to the attachment surface, magnets have weak shear strength and can easily slide across a metal surface – Use of the Magna-Track Mounting System solves the “weak shear strength” problem by locking the twist lock fasteners into their horizontal and vertical position with the track, so they cannot be slid (parallel / inward ) toward the intake opening under the flow of air – making this a highly stable and superior magnetic mounting solution vs. individual magnetic fasteners.

The Magna-Track Connectors utilize High-Energy Neodymium magnets that measures approximately ½ x ½” x 5/16” (15 mm x 15 mm x 8 mm) and provides aggressive surface attachment (approx. 17 – 18 lbs of pull strength per magnet). Magna-Track magnets are triple plated with a Nickel / Copper / Nickel coating to optimize durability and prevent corrosion. Neodymium magnets are a member of the Rare-Earth Magnet family and are the most powerful type of permanent magnets. They are also referred to as NdFeB magnets, or “NIB” because they are composed mainly of neodymium (Nd), Iron (Fe) and Boron (B). Magnets used in the Magna-Track product have a high resistance to demagnetization; unlike most other types of magnets, they will not lose their magnetization when in contact with other

How Magna-Track Connectors Arrive with Your Order:

Track Connectors are universal parts that are available in “Corner” and “T” configuration and are available with or without magnets – They are used to connect lengths of track together to create a linear run of Track or, to connect them into a square or rectangular frame. Since not every application requires the use of magnets, they are supplied along with connectors in quantities of 6 sets per package. NOTE: Magnets are not sold separately without connectors. When you receive your magnets, they come wrapped in a protective tube with spacers between each magnet to help prevent damage and to help you separate these powerful magnets when inserting into the back of the connectors. When separating the magnets, be sure to keep the magnets far enough apart so the magnetic field doesn’t attract them to other magnets or unintended surfaces. If not exercising caution, the magnetic force can cause the magnets to violently slam into one another or into unintended surfaces, risking damage.

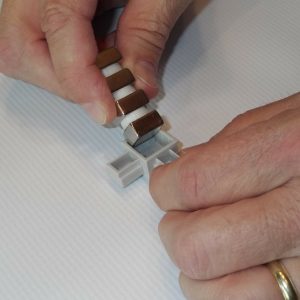

Inserting Magnets into Connectors:

Holding the stack of magnets, simply press the bottom magnet into the cavity on the back of the connector, then slide the stack above the inserted magnet sideways and away from the inserted magnet – be sure to set the stack down at lest 20″ from the connector. Once inserted into the cavity, the magnets will not come out of the cavity. For “peace of mind”, you can add an epoxy adhesive or a two-sided industrial tape into the connector cavity prior to insertion – although this should not be necessary. Because the magnets are sized to fit snugly and permanently into the cavity of the connector, inserting them may require greater strength then pressing them in with your thumb – if that is the case, place the magnet onto a flat surface and press the connector onto the magnet using your body weigh. NOTE: Never use a metal or hard object to strike a magnet as it can fracture the coating and inner structure) When fully inserted into the connector, the exposed surface of the magnet should be flush or slightly higher than the rim of the cavity so it comes in direct contact with the point of attachment.

This innovative magnetic mounting system provides unparalleled flexibility in attaching Cottonwood Filter Screens and Hail Guards to mechanical equipment.

Features / Benefits:

- Reduces Installation Liability – Eliminates Risk Associated with Drilling and Screw Mounting.

- Reduces Installation Time and Cost by up to 50% .

- Mounts to Non-Magnetic Surfaces ( Aluminum, Plastic louvers, Fiberglass, etc.) – By using 1.75″ x 1.75″ 18ga. Magna-Plates that attach with 3M VHB Industrial Two Sided Tape or with mounting screws to Create a Magnetic Mounting Point.

- Colossal Mounting Strength – Retains Filter Over Intake Opening Without Losing Tension – Each Magnet Provides 17-18 lbs. of Pull Strength.

- Attach Magnetic Connectors at Any Interval For Maximum Retention.

- Optimizes Mounting Flexibility by Enabling placement of Filter Screens where Screw Fasteners Can’t be Applied Due to Inaccessibility or Danger of Hitting Sensitive Internal Components.

- Compatible with Both PVC and Anodized Aluminum Track. Magna-Track Connectors and Track, Mounts Flush Against the Mounting Surface – No Gap and No Air Overflow. vs. Competitive Magnetic Toggle Fasteners. Click Here For More Info

- Magna-Track Connectors and Track, Mounts Flush Against the Mounting Surface – No Gap and No Air Overflow. vs. Competitive Magnetic Toggle Fasteners.

- Use of Track with the Connectors Overcomes Weak Shear Strength – Filters maintain tension under flow of air Because the Track Retains Twist Lock Fasteners.

- Can Be Used on Filters which either Have or Don’t Have Back Support under Flow of Air.

- Mounts Vertically and Horizontally to Equipment.

- Enables Removal of Filter, Hail Master or Weather Guards from Magnetically Mounted Frame without removing the magnetically mounted frame – Allows Easy Storage

- Compatible with All HVAC Makes & Models.

- All components are Rust Proof / Resistant.