Cooling Tower Air Intake Screens

Cooling tower air intake or inlet screens, also known as cottonwood filter mesh screens, cooling tower air intake mesh or cooling tower screens, play a crucial role in maintaining the efficiency and longevity of cooling towers. These screens are specifically engineered for use in high volume / high velocity air movement systems with low impact on airflow and static pressure and for the specific purpose of preventing the entry of airborne debris, such as cottonwood seeds, leaves, insects, pollen, dust, sand and other airborne particulate. By installing these screens, the cooling tower’s air intake is effectively protected, resulting in several significant benefits.

First and foremost, the use of cooling tower air intake screens ensures the optimal performance of cooling towers. When debris enters the cooling tower, it can clog the the Fill / Strainers / Blowdown Valves / Heat Exchangers and impede both water and airflow, leading to reduced cooling efficiency. This can result in increased temperature in both comfort and process cooling applications causing an increase in energy consumption and compromised cooling capacity. By acting as a barrier, the screens stop the accumulation of debris, allowing the cooling tower to operate at its full potential and maintain consistent performance. Additionally, the screens contribute to the overall maintenance and cleanliness of the cooling tower system. Without proper filtration, debris can accumulate and create a breeding ground for bacteria, fungi, and other microorganisms including legionella. These contaminants not only deteriorate the water quality, that can pose a health risk to maintenance workers but also impact the operational efficiency of cooling tower’s components. By blocking the entry of debris, the screens help prevent the growth of harmful microorganisms, reducing the need for extensive cleaning and minimizing the risk of equipment damage. To clean the air intake screens simply use a broom, brush, garden hose or leaf blower – It is that simple. Compatible with all makes models and sizes.

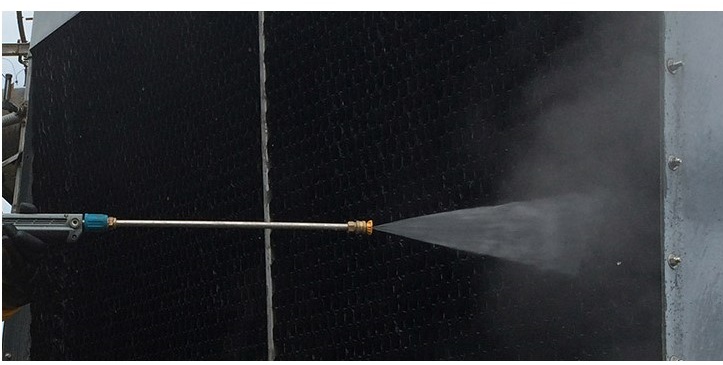

Many people power wash the fill on cooling towers to clean it however, power washing mostly restores only the cosmetic appearance vs. actually, cleaning it because most of the debris gets washed deep into the fill where it causes “water sponging or pooling” reducing the air to water surface contact and prevents water filming which is necessary for optimal heat rejection.

Unprotected Cooling Towers Can Lead To Adverse Effects On Other Parts Of the System And Overall Efficiency